This page archives the recent Luz Azul Project proposal by Eric Hunting for the 2009 Buckminster Fuller Challenge competition hosted by the Buckminster Filler Institute.

Entry Image[]

Entry Text[]

Buckminster Fuller Challenge Entry

Luz Azul – Light Blue

The efficacy of an action upon a whole system is measured by the spread of its cumulative impact through that system. There are no simple solutions to whole problems, but there are straightforward strategies that can seek to maximize cumulative impact. In this proposal we present just such a strategy to address the three greatest and interdependent whole problems of our age; Global Warming, energy, and hunger.

The problem of Global Warming is not merely a consequence of our choice of energy sources. It is a whole problem, integral to the relationship between the logistics determined by the physical characteristics of our dominant energy sources and the evolution of the physical architecture of the civilization around them and thus its definitive solution will ultimately only be realized with a physical restructuring of the civilization as a whole.

There is no brute force solution to this situation due to scale. The simple and obvious solution of eliminating all fossil fuels is hampered by the fundamental incompatibility of the logistical characteristics of renewable energy with the structure of the habitat as it has now evolved and the inability of that habitat to change with any great speed. This incompatibility is the root of all supposed shortcomings of renewable energy that future technology is routinely counted on to overcome –compelling it to be far more advanced to perform the same jobs as older technology the habitat is already adapted to. In a civilization with a physical footprint more like it was in the Steam Age or as envisioned by Paulo Soleri –where most population is urban, living in cities and dense villages, all long-distance transit is mass transit along a limited number of links, and the architecture of the habitat architecturally accommodates these limitations to turn them into conveniences rather than inconveniences– renewable energy would present no complications for implementation whatsoever. No sacrifices, compromises, or future ‘breakthroughs’ necessary because the logistics of renewable energy use would readily match that architecture. But this would demand a wholesale reversal of the dispersion of the civilization’s footprint as it has evolved today. The evolution of the structure of civilization is driven by personal and economic incentives. To alter that evolution we must engineer alternative systems of incentives keyed to new energy and a new urbanism eliminating the inconveniences and economic forces that drive people out of cities. That will take time –especially given that there is so little cognition of the actual nature of the problem by most involved and still persistent ad hoc demonization of the city in our culture. All this is a task of generations.

But were running out of time. Global Warming is already at the point of crisis, as is energy and, as a consequence, global hunger and poverty. To address these crisis in the near-term while also addressing the larger situation of the habitat’s architecture as a whole a practical project must systematically target as many of the weakest points in the armor, so to speak, of our old infrastructures as we can. The points where we can leverage our efforts to the maximum impact and effect the most functional change on a global scale. By focusing the potentially overwhelming economic advantages of renewable resources on these weak spots in this way we can induce shifts in the larger system driven by both market and cultural forces in concert. A project that comprehensively addresses this situation must thus simultaneously address all of the following criteria or objectives;

1) It must implement renewable energy exploitation on a demonstrably large scale.

2) It must put that energy to use in an immediately economically practical way at a global scale using only off-the-shelf technology. In this way it addresses issues of energy shortage while serving as a carbon offset and creating economic incentive for its pursuit.

3) It must address the physics of Global Warming in a direct way and at a large scale, ideally through both offset and direct sequestration of carbon.

4) It must address the socio-economic consequences of Global Warming and energy depletion, such as hunger, poverty, and political strife, in a direct way and at a large scale, providing social incentive for its pursuit.

5) It must present a viable model of a new habitat adapted to sustainability and renewables just as conventional habitats are adapted to fossil fuels and demonstrate the lifestyle benefits of this new habitat and its lack of any shortcomings or compromises compared to the conventional habitat. Marketing change on the premise of altruistic self-sacrifice in a non-starter. It must offer a new advantageous way of life to aspire to.

Quite a tall order. Luckily, nature herself seems to have somehow anticipated our need and presented us with an opportunity for a potential packaged solution that is remarkably straightforward and yet has long been overlooked or dismissed by all but a few visionaries. The sea is our single greatest repository of solar energy. The sum total of our civilization’s energy use is equivalent to about one half of one percent of the solar energy that falls upon the Equatorial oceans. And we have a means at-hand, today, of tapping into that energy with great efficiency and in a way that is simultaneously directly counter to the physical processes producing Global Warming; Ocean Thermal Energy Conversion.

Invented at the end of the 19th century, OTEC uses the difference in temperature between warm surface seawater and cold deep seawater to drive a Rankin cycle system producing electricity. Running on the latent thermal energy in the water for hundreds of miles around, it runs continuously, not just during the day or best during one part of the year. OTEC is a well understood and proven technology with dozens of prototype plants having been built and demonstrated in many countries across the 20th century. But it has long had two critical problems; it only works optimally in the remote open sea near the Equator where surface temperatures are highest and water depths exceed 800 meters and it’s only cost-effective when deployed at large scale, given limitations in net yield common to solar power systems and because of the minimum scale of structures needed to tolerate open sea conditions. In many ways it embodies the essential logistic challenges common to all renewable energy technology. Electric power is normally produced by municipal utilities companies with no interest in running power plants several thousand miles away and no skill set for doing things at sea. And there is no cost-effective way to cable a facility far out on the Equator to the cities of the northern hemisphere. Thus there has been little sustained interest in the technology despite the technical success of every demonstration of the technology to date. Even environmentalists and proponents of renewable energy have largely overlooked it, largely because such large machines cannot be brought down to the level of something one can add to a straw bale house on the edge of wilderness and therefore has no ‘grass roots’ counter-cultural potential. To be effective, OTEC must be deployed in the manner of a self-contained enterprise integrating production and transportation and package its products in a manner suited to global distribution.

However, these logistical problems are overcome when you think about OTEC as more than just a power plant. In fact, an OTEC is a veritable oceanic cornucopia. Consider the common practice of cogeneration, exploiting a conventional power plant’s latent heat to drive industrial processes in adjacent facilities. At one time steam from power plants was distributed, along with power, throughout cities, heating buildings and driving all sorts of businesses from large industrial plants to neighborhood laundries. Now imagine that expanded a hundred-fold in diversity. That’s what an OTEC is like. In addition to producing electricity, an open cycle type OTEC produces tremendous volumes of distilled water, industrial gasses like hydrogen, oxygen, nitrogen, ammonia and methanol produced from those gases, pure salt and minerals, and tremendous volumes of cold nutrient-rich deep seawater. Used as a feed-stock for poly-species mariculture and algaeculture, this nutrient-rich water becomes a source of food, another large spectrum of industrial products, and another secondary source of energy.

This table from the Sea Solar Power Corp. –the leading developer of OTEC systems today– offers a partial breakdown of the potential annual product output of a single 100MW OTEC;

Product(1) Output/yr Unit Price Output/yr Metric Units Unit Price Metric Revenue/yr(1) Electricity 788,400,000 kwhrs $0.12 788,400,000 kwhrs $0.12 $94,608,000 Oxygen 219,000 tons $94.00 198,672 M.Tons $104 $20,586,000 Nitrogen 139,000 tons $82.00 126,098 M.Tons $90 $11,398,000 Ammonia 106,000 tons $170.00 96,161 M.Tons $187 $18,020,000 Hydrogen 17,000 tons $1,900.00 15,422 M.Tons $2,094 $32,300,000 Methanol 26,700,000 gals $1.90 101,059,500 liters $0.50 $50,730,000 Fresh water(2) 21,000,000,000 gals $0.003 79,485,000,000 liters $0.0008 $63,000,000 Fish 32,000,000 lbs. $1.00 14,514,880 kgs $2.20 $32,000,000

(1) Electricity only from first plants. Later plants, according to their design, will have a mix of products. (2) Fresh water plant only; Much higher quantity.

Note that in the above table, hydrogen production is based on the by-product of the de-gassing phase of OTEC operation, not electrolysis. Full potential hydrogen production would be based on conversion of electric power output. Similarly, methanol and ammonia noted are products of the combination of de-gassing by-products including that hydrogen. This does not reflect additional potential methanol, ‘green crude’, or biodiesel production from mariculture, the technologies for which are now just being commercialized. Unit value for electricity is based on retail market cost averages. Fish production is based on simple cold species fish farming and also a volume of discharge based on closed cycle OTEC systems. Open cycle OTECs, as Luz Azul would use, would radically increase this, along with the net fresh water production volume. Using full polyspecies mariculture –a permaculture approach to mariculture– production including extensive algae, shellfish, and diversified fin-fish production would greatly expand over this. For a 100MW OTEC potential mariculture production alone is, by some estimates, worth up to $800 million annually.

In addition would be some 25,000 metric tons annually of directly sequestered carbon by salp cultivation, which one could profit on in carbon credit trade in combination with the potential carbon off-sets. Cool water effluent from an OTEC results in increased algae growth in the waters around it, producing a corresponding increase in the growth of marine salps that consume this algae and produce carbon pellets that sink to the sea floor, sequestering carbon dioxide from the atmosphere. Exploiting this phenomenon for mass carbon sequestration by wave-driven pumps has already been proposed by James Lovelock and is under development by the Atmocean Corp. But even this is small compared to the carbon it would potentially offset in fossil fuel based energy and food production to the tune of 5 million barrels of oil annually or 2.25 million metric tons of carbon. And this is just one plant with a sticker price akin to any common ocean liner or container ship.

Amazingly, in the mix of products generated by an OTEC are all the ingredients necessary to deliver its products to the world. The cold water and nitrogen produced let you refrigerate and preserve the seafood products, seaweed and chitin waste from shellfish can be turned into packaging, and the hydrogen can fuel ships to deliver it. In fact, the lack of any comprehensive land-based infrastructure for the use of hydrogen is a minor issue because we don’t need it for marine shipping.

This is a particularly important point. One of the great logistical challenges for renewable energy has been getting its power to market. You can package that power as liquid hydrogen and transport it like oil, but that doesn’t help you when there is no infrastructure to use that as there is for oil. Thankfully, marine transport is one of those weak points in the old infrastructure. Ships are likely first-adopters of hydrogen fuel use as their large physical scales, ease of retrofit, and potential use of many kinds of power plants like diesel engines, turbines, and fuel cells make them easy to adapt. Already commonly using hybrid electric drive based on generator power plants, the switch to hydrogen fuel is a relatively minor retrofit for many vessels. A recent EU study called H-Ship concluded that, today, there are no technical barriers whatsoever to the implementation of a hydrogen powered commercial shipping fleet. We can do it now, off-the-shelf. No ‘breakthroughs’ required. All that’s lacking is a hydrogen production infrastructure, but that’s no problem for an OTEC based facility producing its own and if there are a series of them along shipping lanes they can fuel a global shipping fleet without concern for the land-based infrastructure.

In fact, current prototype hydrogen ships don’t fuel-up on hydrogen. They generate their own by plugging into the power mains at shore and using electrolysis to fill up bunker tanking. This works both ways, allowing a ship delivering bulk energy from an OTEC in the form of hydrogen to simply plug into the regional power mains and use its own on-board generators to turn that stored hydrogen into electricity delivered to the grid. During the recent power failures in California, Navy vessels were employed just like this, as emergency diesel generator plants. Most urban centers –and consequently most energy production facilities– are coastal. Thus we have a simple means at hand of using hydrogen to deliver bulk renewable pollution-free energy collected at the Equator to the whole world in largely the same way to transport oil, no new infrastructure costs necessary!

Marine shipping is one of the smaller pieces of the energy and carbon load spectrum but it still accounts for about 4% of fossil fuel use, about 7% of the carbon production, and shipping costs –now on the rise with destabilized energy markets– impact the cost of all goods transported by sea in this age of Globalization. So getting renewable energy on-line here is not only much easier than many other approaches, it offers the most global impact in the shortest period of time.

And as if all these OTEC products are not astounding enough, there is even potential to employ mariculture as a means of literally farming the construction materials to support an OTEC with. Though a speculative technology at present, it is theoretically possible to employ mariculture for the production of silicate and aluminosilicate bearing diatoms and calcium-bearing lithophoric algae, providing the basic constituents of geopolymers and other forms of advanced cement. Ultimately, in combination with PSP technology this presents an interesting possibility of being able to literally farm real estate!

Such a diversity of products presents an important advantage in economic stability for an OTEC-based venture. Renewable energy projects are extremely sensitive to fluctuations in the world energy market. But with so much coming out of an OTEC, it has the ability to use gains in different market areas to subsidize its energy prices during periods where its energy values would be soft.

Theoretically, ten thousand 100MW OTEC plants would supply the entire world’s energy needs and if fully utilizing its potential for food production, provide as much food as produced by 4 times the land mass of the entire earth! They would annually replace 22.5 billion metric tons of carbon production and directly sequester 250 million metric tons –effectively offsetting and reversing the entire civilization’s carbon production. And, of course, that many OTECs on-line would subtly cool the equator, reducing the generation of storms and, over a long time, countering the increased temperatures globally. Global Warming, energy shortage, and hunger, gone, all with one renewable energy technology and one straightforward plan.

At a rough cost of about $300 million dollars each, ten thousand 100MW OTEC plants would have a cost of about 3 trillion dollars today –about what the US recently spent, by many estimates, on the war in Iraq. But constructed alone atop a SPAR platform or the like, an OTEC can only exploit a tiny portion of its potential. Full utilization of its many output resources demands space on-location for industrial facilities of some scale. Industrial scale mariculture in particular would require large shelter structures, significant manpower, and significant processing and shipping facilities. To accommodate this it would be necessary to construct facilities on par with a modest community; a floating marine colony hosting some thousands inhabitants and up to a dozen OTEC plants each. The term ‘marine colony’ is commonly associated with science fiction, but in fact there are no technical obstacles to their creation. The actual obstacles have been largely logistical, associated with limitations in transportation and economic subsistence that are readily solved by OTEC. Using currently available Pneumatically Stabilized Platform structures based on concrete construction using more modern low-carbon alternatives to cement like eco-concrete and geopolymers, one can construct marine facilities of any scale at a current initial cost of about $1000 per square meter relative to nearest land facility labor costs.

PSPs function as their own breakwater, completely absorbing all wave action of wavelength shorter than their cross section. This is exploited for energy through the use of turbines in an integral duct network. Near shore, a platform’s entire power needs can be supported by this power source. On the open sea, however, it is used primarily for station-keeping purposes. Active station-keeping by GPS controlled azimuth thrusters would eliminate the untenable costs of deep water mooring systems and allow slow mobility for the entire structure. Vectoring discharge from OTECs can also serve a station-keeping purpose.

PSPs also have the great virtue of being both modular and able to use their own platform as a construction facility for modules, greatly reducing the cost of construction of larger platforms and allowing a facility to retain this capability perpetually for later expansion and for-profit structure production. Combine this with the potential for farming materials for such construction by mariculture and colonies have the ability to grow and self-replicate like a living organism, alternately expanding and budding-off copies of itself free to self-propel themselves to other locations.

Potential concepts for marine settlements vary wildly in design and, given the versatility of PSP structures, one can build as freely as one does on land, employing the full spectrum from the industrial or purely functional to the outrageously fanciful. The chief design limitation is that the environment and the current cost of structures precludes the grossly inefficient strategy of individual free-standing houses. One must build unified community structures with an urban density, though the relative manpower to structural space ratio for OTEC derived industries could leave individuals with more personal space than common to even American suburban housing.

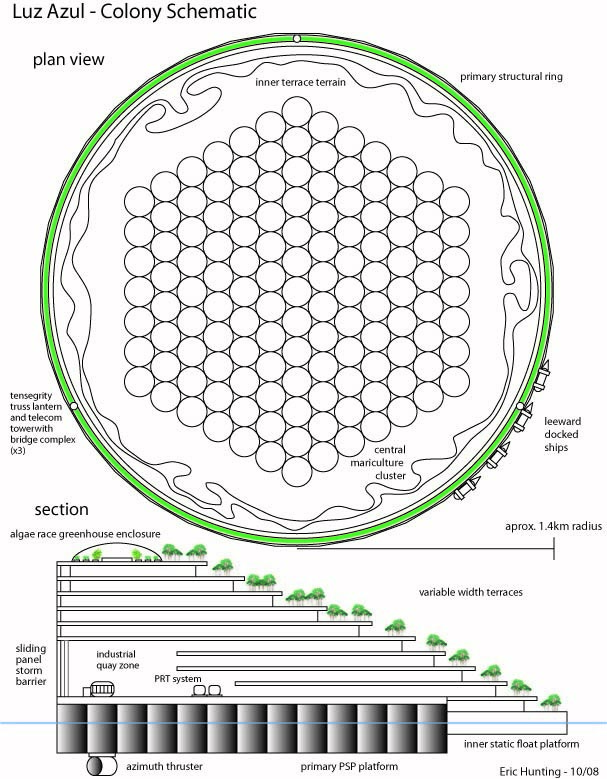

In terms of functional features, a typical colony would be organized as one or more bays or lagoons sheltered by the platform structure with each 100MW OTEC deployed requiring about ten million square meters of habitat space enclosing about 2000 hectares of sheltered mariculture pond space and supporting 1000 or more inhabitants, depending on the mix of secondary industries. A full-scale colony may feature anywhere from three to twelve such OTECs, the colony scaled accordingly. A terraced habitat structure is the most practical, placing all habitable space inside terrace edges and leaving the top surface free for farming and parkland, helping to moderate the Equatorial climate (though the OTECs would also drive habitat air conditioning) while making for a very aesthetically pleasing environment. The perimeter edge of the platform would function as the primary storm barrier for the structure with an edge height of about 15 meters faced by concrete. Near the location of the OTEC plants a grill-covered warm water intake vent would face the cylindrical platform structure, discharge vents being separate and at lower depths or located on an opposite –leeward- side.

For simpler colony forms, such as simple rings, the leeward side of the colony would be able to function directly as a quay-side for the mooring of ships sheltered by the wave absorbing nature of the structure, the base platform deck height the same as large vessel quays and well suited to RoRo (roll-on roll-off) transfer. Straight edges formed by a polygonal edge shape would provide ready mooring points while storm barriers in the form of large sliding panels would be designed to open for access to the lower interior structural decks and deployable cranes. Outward-facing habitat decks at the top of the structure would serve as ready port control facilities with unobstructed views of ship traffic for hundreds of miles. Ships would station-keep in the leeward open water near the colony, docking only during transfers. Small vessels would be hoist whole and stored in the platform interior. However, since the leeward side of the colony may change with the weather, the colony as a whole would need to rotate to maintain shelter of docking facilities or employ them uniformly around the perimeter, compelling docked vessels to change position. While suited to smaller earlier colonies, this approach may become less practical for the larger structures, necessitating the use of dedicated shipping bays or the use of secondary independent perimeter breakwater structures near docking areas. Such structures would employ simple rectilinear forms and could serve such additional functions as toxic fuel storage and light aircraft airstrips akin to extremely large aircraft carriers with structurally integral hangar space.

Most of the whole area of a typical colony would be dominated by bays and their mariculture structures. For polyspecies mariculture these would be organized into at least four zones accommodating the four general types of culture relative to nutrient density of the OTEC discharge water. First would be algaeculture that, initially, would employ raceway trough structures under a large greenhouse on the highest levels of the structure. This greenhouse would also serve for hydroponic farming. Next is shellfish feeding on algae, followed by crustaceans and then fin-fish. Mariculture systems would employ net or cage pen structures as well as more isolated membrane enclosures, some of which may use fresh water from the OTEC open cycle distillation rather than saltwater. A largely standardized modular form would be used for these systems based on large polyethylene or masonry float structures supporting catwalks.

Factoring in savings from large-scale platform construction and additional costs for superstructure architecture and industrial facilities, we arrive at a rough production cost of ten billion dollars per fully deployed 100MW OTEC with the necessary industrial facility, mariculture, and habitat space supporting it. Based on this we arrive at a ‘guestimate’ for the cost of deploying ten thousand OTECs around the Equator –the cost of replacing all fossil fuel energy, stopping Global Warming, and eliminating all hunger at least in terms of supply– of about one hundred trillion dollars –roughly, the entire annual GNP of the planet for one to two years.

This would seem a rather ridiculous proposition if one didn’t take into account that one need not build such facilities all at once, or that they wouldn’t actually pay for themselves. In fact a full size colony exploiting all its possible sources of revenue should be able to pay for itself in five to ten years from completion. This means that, reinvesting its own revenue in order to reproduce itself exponentially, one full-scale marine colony could effectively become one thousand in fifty years at an end-cost of…nothing to any governments. This calculation does not account for likely decline in cost of the technology involved. Old as it is and despite being available from a number of companies, OTEC technology has not, because it has remained underutilized, enjoyed the benefits of refinement. Significant improvements in performance and reduction in cost are likely given concerted production and use of the technology. Similarly, our cost estimates for PSP structures are based on shore-based on-demand construction. With mass production on-site and refined over time and with the materials for production potentially farmable at sea using mariculture techniques, radical reductions in cost are possible. It’s not possible to predict with any accuracy how much improvement might result, but it is safe to assume that subsequent expansion and replication of these colonies will come with steadily declining costs and any such improvement would increase the speed of an already impressive pace of growth.

This is a very important point. Most plans for carbon sequester –or geoengineering as it is coming to be called– cannot actually pay their own way. They demand governments to front their huge expense for a long time without any financial return on investment. Not only would marine colonies pay for themselves, they would boost the global economy, generate huge food surpluses to donate to global hunger relief, and create new jobs and homes for millions, all at no net cost to any taxpayers.

It would seem, then, that marine colonization as we have outlined here offers, perhaps, the single-best strategy possible for addressing these three greatest challenges of our age. Thus we arrive at our ultimate proposal; Luz Azul – Light Blue.

Luz Azul is the name given to the first of a planned series of marine settlements. Intended as a more modest quarter-scale demonstration of the potential of this plan of development, it would be a 3 billion dollar project producing a settlement hosting one OTEC plant, 500 hectares of mariculture space, three modest scale hydrogen powered vessels –cargo, energy ‘tanker’, and packet/passenger ship–, the necessary but down-scaled industrial facilities for full OTEC utilization, housing for several hundred resident inhabitants. It would be built with the intention of incremental expansion to 2000 hectare area and then to a full scale colony of three to six times that size based on replication of its primary structures.

Due to smaller initial scale, this first settlement would be equatorially located but relatively close to an existing land location with a potential immediate market for its products. Its packet cruiser –if not all its vessels– would employ a SWATH or other fast-ship hull design intended to make commutes to the land as quick as possible –though in this jet age even at 40 knots one can only do so much in this respect for a facility hundreds of miles from shore. Likely locations would be in the Pacific and Indian oceans in some proximity to the major continents.

Flying some flag of convenience like any commercial vessel and founded as a commercial venture by a consortium of companies, Luz Azul would employ a Kelsonian economic strategy based on the creation of an umbrella Community Investment Corporation with residents as shareholders in their community and all its business ventures. This not only insures just equity among the colony residents, it insures that property rights are not limited to specific spaces in specific locations, leaving the community free to structurally evolve –a very necessary ability for such a project and a very important factor in its local cultural development that would be reflected in the design of residences that would be spacious and comfortable but also spontaneously adaptable through retrofit. Seeking to expand to full scale as quickly as possible, the community would use itself as its chief marketing tool for seeking investment and to initiate as many derivative business ventures as possible. This may involve extensive tourism development with the creation of a local resort facility and marine recreation complex. Growing like the algae it cultivates, Luz Azul would self-replicate, budding off copies of itself set free to move on their own to new locations, expanding the marine community into a globe-spanning network. Over time the Luz Azul CIC may become one of the largest multinational corporations in the world, dominating marine shipping and supplying bulk seafood and renewable energy to every continent.

Initially, the small size of the community and its remote location would create some inconveniences for its residents due to a lack of amenities and travel convenience. We are lacking in necessary transportation options to support such remote communities adequately by western standards and inhabitants would be limited to travel by surface ship for most of their needs as the population levels needed to support conventional airliner service would be untenable. This is one of the key logistical issues that have traditionally plagues the marine settlement concept and a key reason for making this a permanently habitable community rather than a temporary work-residence as with oil rigs. This may be ameliorated by future VTOL air transit technology, some of which these communities themselves may pursue the development of. But to compensate for this in the near-term, the community would seek to create a very comfortable, attractive, and efficiently integrated local habitat offering generous personal space and pursuing local development of as many services and amenities as possible, and provide public transport by relatively comfortable cruise liner service. Supporting tourism from the start would aid in this, allowing for the creation of many recreational and service amenities that the small initial resident population alone might not justify alone and, more importantly, serving to help disseminate the experience of its very comfortable renewable-energy-based sustainable lifestyle. But even without this, the potential revenue from these colony ventures relative to the colony population should assure a quite comfortable lifestyle for their inhabitants.

Though based on a modular structure, a relatively organic approach to the colony architecture could be employed, its terraces assuming flowing contours akin to a topographic map that would enhance its naturalistic appearance. Basic colony design would be organized around a single large bay ring hosting mariculture, recreational facilities along its inner perimeter, shipping and industry on its outer perimeter. An automated Personal Rapid Transit system able to host ISO containers in addition to human passengers would run through the core of the ring structures and form the basis of many convenience services like automated packet transit and automated personal storage. Container storage would be internal, located on the vast base utility deck of the PSP structure, while bulk materials storage would use submerged tanking or hopper storage integrated with the PSP cylindrical cell structure itself.

Obviously, the cost of the Luz Azul project is beyond the scope of the Buckminster Fuller Challenge. Ultimately, its creation will depend on a consortium of corporate investors and possibly government programs supporting Global Warming abatement efforts. Therefore, proceeds from this competition would be employed in the creation of the initial development company for Luz Azul and for the organization of an international architectural design competition to create a compelling colony design that can be used as the basis of a marketing campaign for the project –a conventional strategy for projects of this scale commonly employed with commercial real estate and tourism ventures. Using this marketing media aid, the project would seek to assemble a consortium of approximately 6 major companies in the area of OTEC engineering, PSP platform engineering, diversified marine engineering and construction, mariculture, commercial shipping, and resort development. Additional small businesses would be recruited as resident service providers, such as common community venders, restaurants, and the like while facility space may also be leased to marine research institutions and telecommunications companies.

With Luz Azul’s definitive demonstration of the positive environmental impact of OTEC, the economic and lifestyle potential of marine settlement, and most importantly a timely and generous return on investment, a steady flow of investment –as well as likely copy-cat ventures– are sure to follow, setting the project well on the way toward achieving its goal of overcoming this century’s greatest challenges while establishing a novel and sustainable new branch of the civilization with potentially great and progressive cultural impact on the world as a whole.

Eric Hunting - 10/08